Stones Tiles Glass Metals Water Jet Machine

45 Degrees CNC Water Jet Cutting Machine

This is a hot-selling cnc water jet cutting machine.

You can adjust its cutting angles between 0-72 degrees. When you need the sink, 0 degrees would be your best choice. When you need the kitchen countertop, that would be 45 degrees.

It can also realize the 3D cutting with 3D software.

You can adjust its cutting angles between 0-72 degrees. When you need the sink, 0 degrees would be your best choice. When you need the kitchen countertop, that would be 45 degrees.

It can also realize the 3D cutting with 3D software.

Product Details

Parameter

AC-5axis Water Jet with 45 Degrees

| Series | AC-5axis Water Jet |

| Cutting Angle | 0-±72 Degrees |

| Table Size | L: 3000-4000mm W: 1500-2000mm |

| Cutting Precision | ±0.1mm |

| Cutting Speed | 2500mm/min |

| Motor | SIEMENS 37kw / 50hp |

| Warranty | 1 Year |

| Certificate | CE, ISO |

| Delivery Time | 45 Days |

| After-sales Service | Field Installation Online Service |

| Loading Container | FCL 20GP / 40GP |

| Loading Port | Foshan Guangzhou |

We are one of the earliest Chinese factories that research, design, produce, and sell the AC-5axis CNC water jet cutting machine.

With the device of the laser scanning, it can auto measure the actual distance between the cutting head and the materials, then it saves in the software. During the cutting, it can auto adjust the height of the cutting head.

For the updated software, it not only can change its cutting angles and speed but also can slow down its cutting speed when it meets the corner.

The special design of the sand valve, we use the motor instead of the manual, and let the sand consumption control within 20kg per hour.

As an intensifier pump that owns years’ experience, series 450 waterjet pump is updating all the time.

Free waterjet software, the language would be Chinese, English, Russian, France, Spanish and Vietnamese. The software is easy and ensures your workers would study and operate it in a short time.

| Model | SH-3015 | SH-3020 | SH-3520 | SH-4020 | |

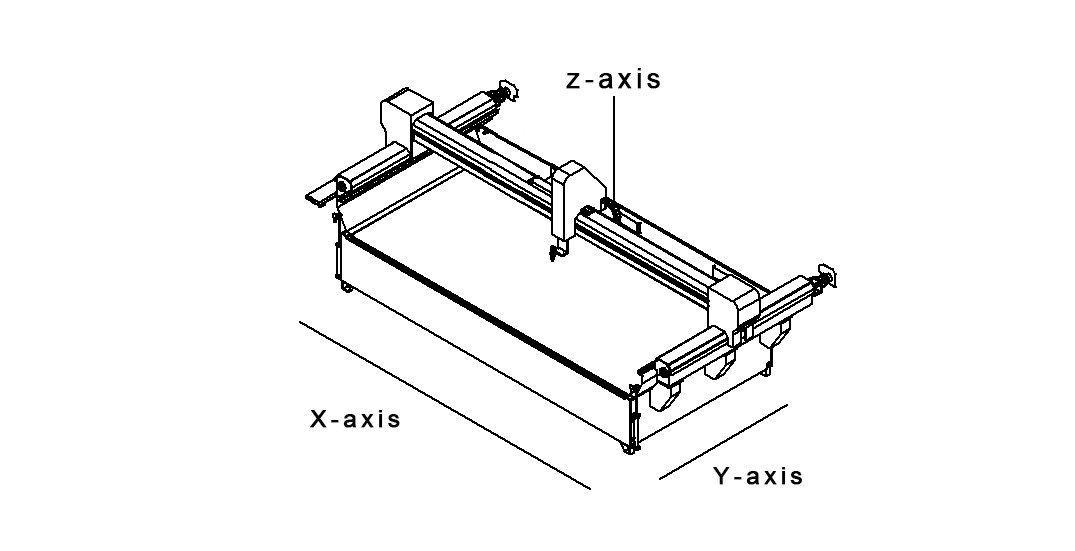

| Table Size | X: 3000mm Y: 1500mm |

X: 3000mm Y: 2000mm |

X: 3500mm Y: 2000mm |

X: 4000mm Y: 2000mm |

|

| 45° Cutting Size | X: 2700mm Y: 1250mm |

X: 2700mm Y: 1650mm |

X: 3200mm Y: 1650mm |

X: 3650mm Y: 1650mm |

|

| Cutting Angle | 0-±78° | ||||

| Cutting Accuracy | ±0.01mm | ||||

| Max Pressure | 450mpa / 65000psi | ||||

| Working Pressure | 340-360mpa / 49300-52200psi | ||||

| Max Water Discharge | 3.7L / min | ||||

| Motor | 37kw / 50hp | ||||

| Sand Consumption | less than 20kg/h | ||||

| Power Consumption | less than 25kw/h | ||||

| Max Thickness (Straight Cutting) |

Porcelain Tiles | 40mm | |||

| Marble | 120mm | ||||

| Granite | 110mm | ||||

| Glass | 80mm | ||||

| Mosaic | 80mm | ||||

| Steel | 60mm | ||||

| Stainless Steel | 60mm | ||||

| Aluminum | 80mm | ||||

| Copper | 80mm | ||||

| Wood | 150mm | ||||

| Plastic | 200mm | ||||

| Foam | 200mm | ||||