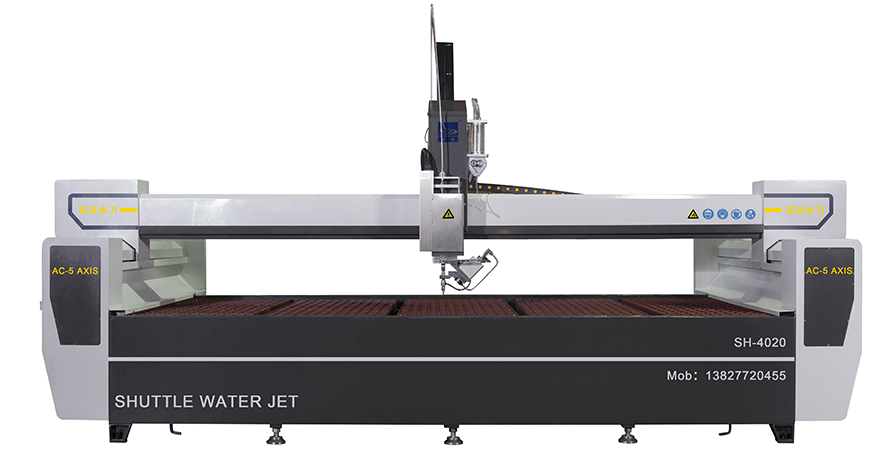

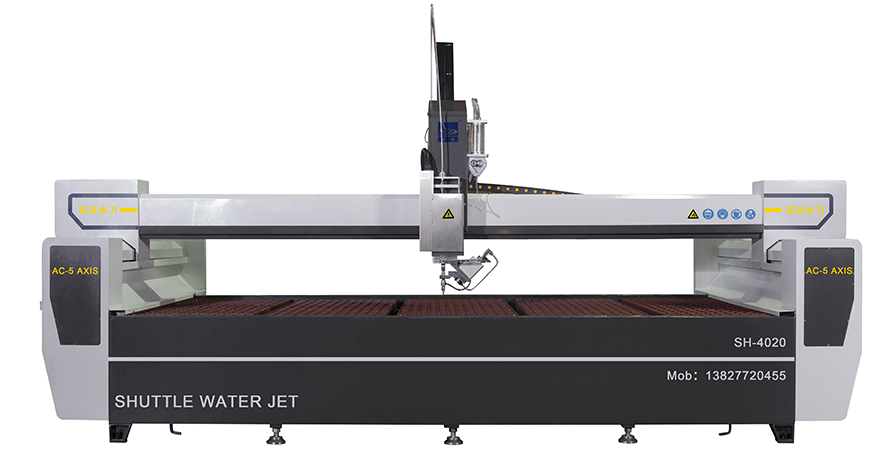

Introduction to related processing technology of waterjet cutter machine

In order to better reduce the cost of industrial cutting processing, engineers are constantly exploring the related technology of waterjet cutter machines, so they invented the waterjet. As the name implies, the waterjet uses water as a knife. The medium forming the knife is water. It can also be recycled and it is simply a perfect and pollution-free green cutting "material". Now the waterjet can effectively reduce costs to create greater profits. Therefore, it is necessary to learn more waterjet application techniques to use low cutting costs to create greater profits.

As far as cutting costs are concerned, the waterjet processing industry is now considered to be a rapidly developing industry. At present, the waterjet cutting machine is currently a high-capacity machine in the world. The waterjet processing technology is now such as flame cutting, plasma processing, and laser Machining, EDM and turning milling are more popular. Waterjet cutting will not generate harmful gases or liquids, and will not generate heat on the surface of the workpiece. It is truly multifunctional, efficient, and cold cutting. .

Waterjet cutting can do processing that cannot be done by other processes. It can perforate titanium and cut various patterns on stone or glass. These all show the uniqueness of waterjet itself. It does not generate heat when cutting the material. In this cold processing process, the supersonic water arrow it produces can achieve the desired effect when it shoots on the surface of the cutting material. The mixing of water and sand enhances its cutting ability. .

As far as cutting costs are concerned, the waterjet processing industry is now considered to be a rapidly developing industry. At present, the waterjet cutting machine is currently a high-capacity machine in the world. The waterjet processing technology is now such as flame cutting, plasma processing, and laser Machining, EDM and turning milling are more popular. Waterjet cutting will not generate harmful gases or liquids, and will not generate heat on the surface of the workpiece. It is truly multifunctional, efficient, and cold cutting. .

Waterjet cutting can do processing that cannot be done by other processes. It can perforate titanium and cut various patterns on stone or glass. These all show the uniqueness of waterjet itself. It does not generate heat when cutting the material. In this cold processing process, the supersonic water arrow it produces can achieve the desired effect when it shoots on the surface of the cutting material. The mixing of water and sand enhances its cutting ability. .